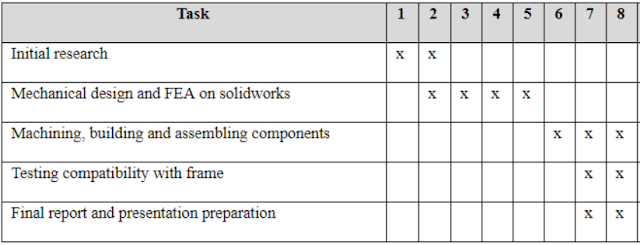

Last week (Week 6), the group worked to finalize the drawing and prepare the project for machining. This consisted of adding small changes to the final design in order for force to be distributed better, and for the pedals to function in a safe manner.

This week (Week 7), the group primarily focused on the machining of the pedal box.

Before the physical machining took place, David added a spot on the throttle pedal for a throttle cable. The throttle cable works to physically connect the pedal and the throttle plate, which helps control the cart's acceleration. For more information on this, please check out the link and description in the 'Background' section. David also finalized the drawing for the throttle pedal.

David also took the stock to size to machine next week. This will help the group start the overall process of machining.

Additionally, on Tuesday Scotty from the Drexel Machine Shop turned our DXF file into a mastercam file. These two files are used in order to manufacture the part from the 3-D model. He made toolpaths, added the tools to the file and then incorporated the feeds and speeds for the machine. Then he placed the 5/8 aluminum sheet onto the machine and set it up using two toe clamps. He did all the interior pockets. Once those were done he removed those and added a center clamp to do all the external features. During this process Scotty showed Lauren how to set up the stock on the mill and how to clamp it down.

This week (Week 7), the group primarily focused on the machining of the pedal box.

Before the physical machining took place, David added a spot on the throttle pedal for a throttle cable. The throttle cable works to physically connect the pedal and the throttle plate, which helps control the cart's acceleration. For more information on this, please check out the link and description in the 'Background' section. David also finalized the drawing for the throttle pedal.

David also took the stock to size to machine next week. This will help the group start the overall process of machining.

Additionally, on Tuesday Scotty from the Drexel Machine Shop turned our DXF file into a mastercam file. These two files are used in order to manufacture the part from the 3-D model. He made toolpaths, added the tools to the file and then incorporated the feeds and speeds for the machine. Then he placed the 5/8 aluminum sheet onto the machine and set it up using two toe clamps. He did all the interior pockets. Once those were done he removed those and added a center clamp to do all the external features. During this process Scotty showed Lauren how to set up the stock on the mill and how to clamp it down.

Finally, Lauren machined the brake pedal twice. Due to some small imperfections in the first attempt, the group thought it best to machine it again, and make sure the design was perfect. The brake pedal is yet to be completed, as the group is waiting on the bearings to arrive. Once they arrive, the holes in the pedal box can be made the appropriate size, rather than estimating from the online measurements.

Lauren also assembled the balance bar and the master cylinder systems on the brake pedal. Due to the detail in the CAD, there was no problem with the overall construction.

The group also worked on the final presentation and report throughout the week.

For next week (Week 8), the group will continue to work on the manufacturing of parts for the pedal box, and they will work to finish the final report and the final presentation.

Comments

Post a Comment